✓ AGGREGATES RAW MATERIALS

✓ ARMOUR ROCK / BOULDERS

✓ DRILLING

✓ GEOCHEMICAL LAB TEST

✓ MATERIAL TESTING

✓ GEOLOGICAL MINERAL RESOURCE

✓ EXPLORATION

• GEOLOGICAL AND GEOTECHNICAL ASSESSMENT

• GEOHAZARD ASSESSMENT

✓ SURVEYING

• RELOCATION

• TOPOGRAPHIC

• VOLUMETRIC

• BATHYMETRIC

✓ AGGREGATES RAW MATERIALS

✓ ARMOUR ROCK / BOULDERS

✓ DRILLING

✓ GEOCHEMICAL LAB TEST

✓ MATERIAL TESTING

✓ GEOLOGICAL MINERAL RESOURCE

✓ EXPLORATION

• GEOLOGICAL AND GEOTECHNICAL ASSESSMENT

• GEOHAZARD ASSESSMENT

✓ SURVEYING

• RELOCATION

• TOPOGRAPHIC

• VOLUMETRIC

• BATHYMETRIC

Products

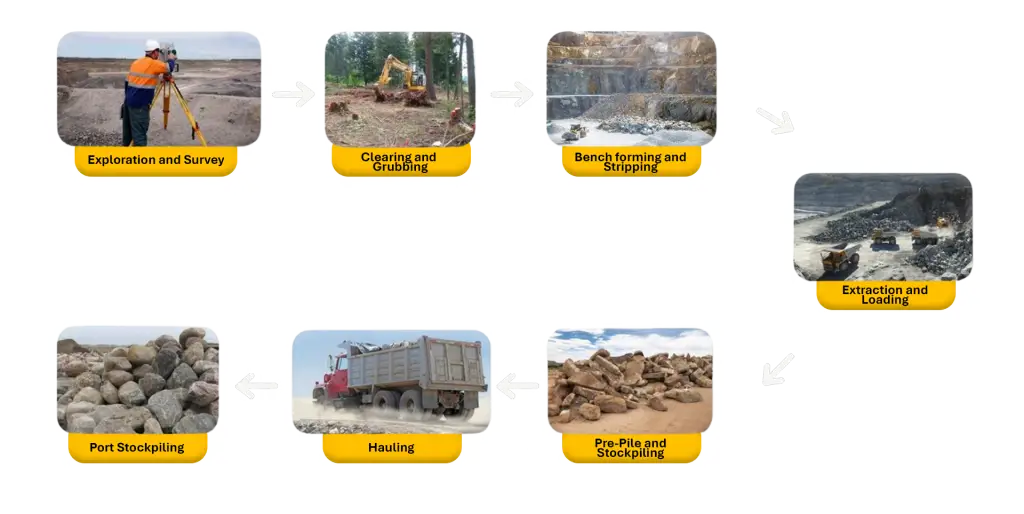

Actual Site Execution

Exploration, Extraction, and Mining

4 Phases of PIMI Mine Project

1. RE-CONSTRUCTION

✓ Planning of technical design and finalization of quarry plans and construction method for the installation of facilities;

✓ Soil investigation prior to civil works; and securing of necessary permits

2. CONSTRUCTION

Construction phase involves the following:

✓ Hiring of qualified manpower required to complement the workers in the construction works.

✓ Hiring of qualified local residents will be prioritized at this stage. Company guidelines and policies on hiring will be imposed;

✓ Site clearing and stripping of over burden;

✓ Access road development;

✓ Establishment of drainage;

✓ Construction of settling pond, office buildings, housing and other quarry buildings; and

✓ Preparation of loading pad and benches.

3. OPERATION

✓ The quarry operation will employ the open-cut mining method. Proper benching shall be employed in each quarry sites. Once over burden has been stripped, terrace-like extraction faces are cut from the topmost strata progressing downward to serve as quarry levels for positioning equipment that will conduct excavation and loading activities. PIMI will construct a main haulage road going in and out of the quarry and to connect the production benches. The series of production benches shall be interconnected to each other by ramps for easier access and to maximize the deposit. Quarrying will be executed by multiple benching pattern to provide greater operation flexibility and production output. Open face extraction of benches is accompanied by a process cycle of excavation and loading, until bench design limits are arrived at.

With repeated process cycle, bench advances are done laterally. The working bench is maintained by systematized programming of earlier extraction of upper benches. Once the bench design limit is reached, the process is transferred to another prepared working bench. Bench height will be limited by the maximum reach of the loader or excavator to be used while bench width shall be governed by final pit slope, loading system and size of haul truck to be utilized. Drainage canals of sufficient depth to handle storm runoff will be laid along the bench toe, and berms with an average height will be provided for the unprotected crest site for added safety. Drilling and blasting will be utilized in the project operation. The quarry will operate on a single shift a day to utilize daylight.

4. PROJECT CLOSURE, FINAL REHABILITATION AND DECOMMISSIONING

Upon exhaustion of the reserves, quarry rehabilitation and decommissioning works shall immediately be implemented. Activities in this phase include:

✓ Mobilization of equipment out of the quarry area;

✓ Rehabilitation of remaining mined-out areas, and settling ponds in accordance to the planned land use program of the Local Government Unit (LGU);

✓ Decommissioning of quarry ancillary facilities;

✓ Implementation of post mining social programs; and

✓ Transfer/donation of buildings to interested LGUs.

A Final Mine Rehabilitation and Decommissioning Plan (FMRDP) will be prepared and submitted to the Mines and Geosciences Bureau (MGB) for review and approval. Among the plans to be considered are appropriate rehabilitation and decommissioning plans that will best benefit the community.